Professional Backflow Installation for Commercial Ice Machine — Tampa, FL

In late July 2025, our plumbing team responded to a service call in Tampa, FL regarding an ice machine installation requiring backflow protection. Upon inspection, we quickly identified a potential risk of cross-contamination between the ice machine water line and the potable water supply. In commercial kitchens, preventing reverse water flow is essential to maintain sanitary conditions and meet health code regulations. This job exemplifies how critical backflow prevention services are in protecting drinking water systems from contaminants.

We selected a reduced pressure zone (RPZ) backflow preventer, a device well-suited for high-risk applications like commercial ice machines. The install involved brass fittings, pro-press copper connections, threaded pipe, Teflon tape, and precise pressure testing. Using our professional-grade tools, we ensured every joint was secure and leak-free.

Installation was performed in a confined utility space requiring careful navigation around dishwasher lines and electrical conduit. Our plumber utilized flexible ratchets, compact torches, and mirror scopes to work efficiently and ensure code-compliant connections despite the limited access.

After testing and verifying performance, the new backflow system was fully operational and compliant with Tampa plumbing codes and AWWA standards. Our client now benefits from a safe, dependable water system free from backflow risks, reinforcing our commitment to expert-level commercial plumbing solutions.

Getting started: Here we’ve laid out essential tools including pro-press connectors, RPZ valve, and pressure gauge. Preparation is key when configuring backflow prevention assemblies for commercial ice machines.

Early pipework installation: We’ve started setting up copper lines using sweat fittings and compression valves. Each joint is cleaned and sealed to ensure leak-free water flow and proper directional protection.

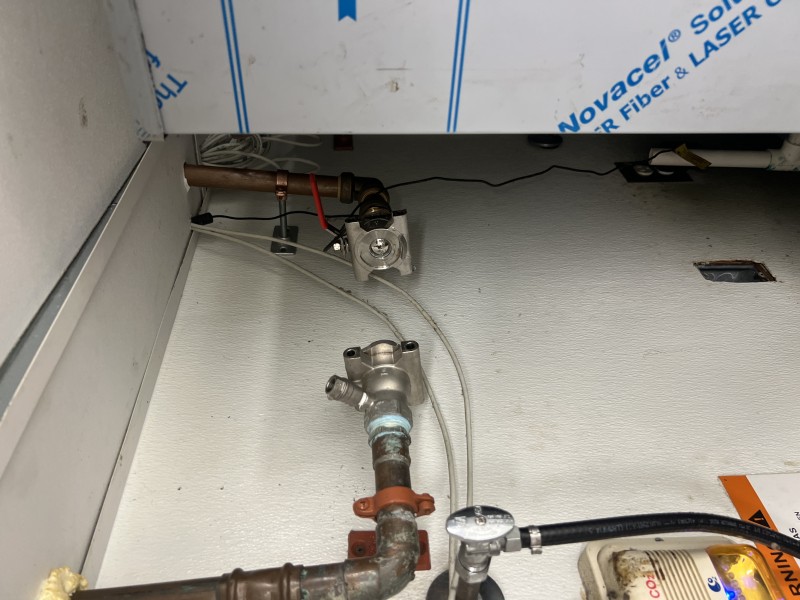

A close-up of the RPZ backflow device connected to the main supply. This assembly is designed to discharge water if pressure imbalance occurs, safeguarding against contamination in high-demand systems.

Here, we route copper and PVC lines through a congested utility room. This setup required precision cuts and careful threading using tubing benders and emery cloth to avoid disrupting nearby equipment.

Final assembly phase: The backflow device has been installed and braced. We’re now pressure testing and flushing the line to ensure full operational integrity. Clean, pressurized water is now safely flowing to the appliance.

Job complete: The backflow preventer and associated piping are in place and functioning as designed. This installation meets local plumbing code and ensures long-term safety for commercial water supply lines.