Commercial Dishwasher Repipe with Booster Heater

Brandon, FL

We completed a full repipe job for the commercial dishwasher system at a busy restaurant in Brandon, FL. The scope included replacing all hot and cold water supply lines to and from the dishwasher and reconnecting the booster heater system for consistent sanitation-grade water temperatures.

Old galvanized piping had begun to corrode and restrict water flow, compromising operational efficiency. Our team installed high-temperature rated PEX and copper lines, pressure-tested every connection, and insulated all exposed lines to maximize energy efficiency and minimize heat loss.

Job was completed overnight to avoid disrupting restaurant service, and we confirmed everything from backflow prevention to final drainage integrity met commercial plumbing codes.

Initial Access

We opened up the access panel behind the commercial dishwasher and traced the full path of the supply lines. Many of these lines were outdated copper with signs of scale buildup, reducing water pressure to the booster heater and sprayer heads.

Old Lines Removed

After isolating the water supply, we removed the aged copper lines. These corroded pipes were a clear hazard for any commercial food service operation, and replacing them ensured reliability and code compliance.

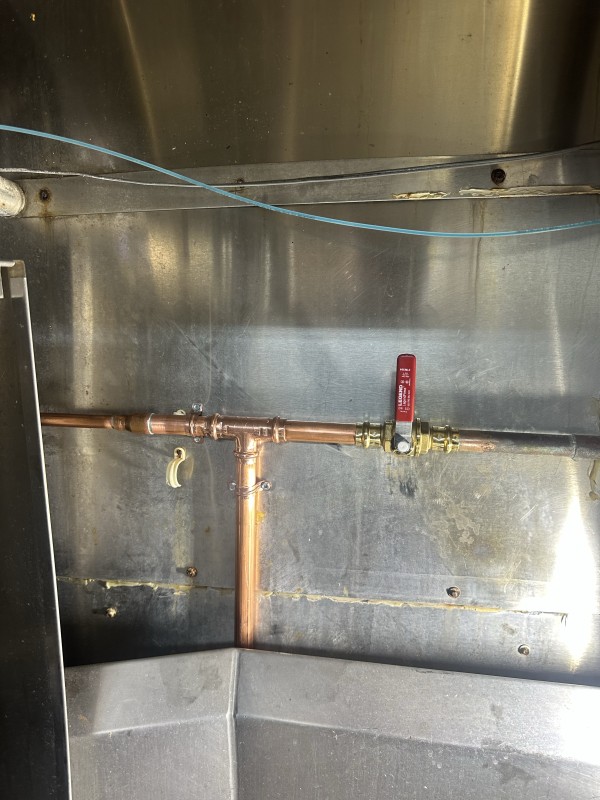

New Copper Installed

We installed new 3/4" copper water lines from the main manifold to the dishwasher input, using lead-free solder and proper flux. All joints were brazed and tested under full operating pressure to ensure zero leaks.

Booster Heater Connection

Here we tied the high-temp water supply into the booster heater using high-pressure flex lines and dielectric unions. This ensures the heater maintains NSF-compliant sanitation temperatures at the dishwasher output.

Pressure Testing

We pressurized the entire water circuit and checked all valves, shut-offs, and unions for leaks. In commercial plumbing, thorough testing is key before re-energizing booster systems and final hookups.

Insulation for Efficiency

All newly installed hot water lines were wrapped with high-R-value insulation to maintain temperature and reduce energy costs, a critical step in commercial kitchen plumbing.

Clean Final Install

All pipes are aligned, anchored, and labeled for future maintenance. We always leave our work looking clean and professional to ensure easy inspection and longevity.

Backflow Protection

This shot shows our verification of the backflow preventer device. Every commercial dish line must have proper backflow to prevent contamination of potable lines—especially in high-use systems.

System Flushed & Calibrated

After installation, we flushed the system and monitored temperature at the rinse cycles. Adjustments were made at the booster heater to ensure optimal sanitization temperature per local health code.

Clean Job Site

We left the mechanical room fully cleaned, with all debris removed and job details logged. Commercial repipes are all about function, but we pride ourselves on presentation and cleanliness too.