Copper Manifold Replacement — Hot Side Behind Lavatory (St. Pete Beach, FL)

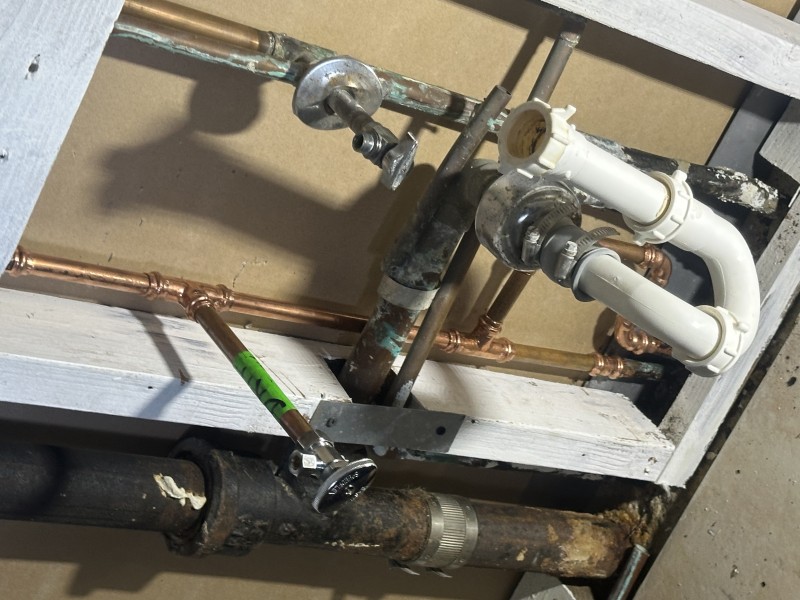

Earlier this week in St. Pete Beach, FL, we were called to diagnose a persistent pinhole leak and visible corrosion on an original copper manifold positioned low behind a lavatory. Left alone, that combination can restrict hot water flow and lead to hidden water damage.

We shut down the main, drained the lines, and opened access to the manifold area. Using a tubing cutter for clean, square cuts, we removed the compromised copper and thoroughly deburred the pipe ends to prep for leak‑free soldering.

Next, we dry‑fit the replacement copper manifold and fittings, applied flux, and heated the joints with a plumber’s torch to create strong, uniform solder beads. The focus was restoring the hot water side while maintaining balanced flow at the lavatory.

With the new manifold in place, we performed a pressure test, flushed the system, and verified stable water pressure and temperature for a durable, code‑compliant repair.

Assessment: Corroded Copper

The original copper manifold showed oxidation and staining near joints at floor level—classic conditions for pinhole leaks and reduced hot water pressure.

Preparation & Removal

We isolated the water, drained the lines, and used a tubing cutter for clean, square cuts. Proper deburring prevents turbulence and helps solder wick evenly.

Install & Solder

We dry‑fit the new copper manifold, applied flux, and soldered with a plumber’s torch to form smooth fillets for a durable, leak‑free connection on the hot side.

Test & Verify

We performed a pressure test, flushed the lines, and confirmed balanced hot water flow—an efficient copper pipe repair ready for years of service.