Gen 3 Tru Tankless Water Heater — Professional Installation

Location: St. Pete Beach, FL | Completed: November 2025

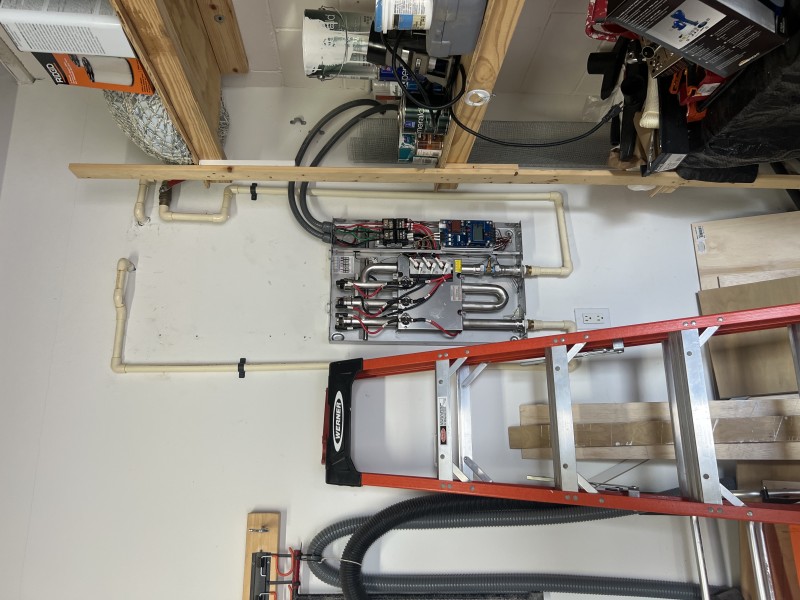

For this project, I replaced an aging tank-style unit with a Gen 3 Tru Tankless water heater to deliver on-demand hot water and boost energy efficiency. I began by shutting off and draining the system, verifying gas supply, and confirming venting clearances. Detailed prep — from checking water pressure and gas line sizing to inspecting copper/PVC runs — ensured a clean, code-compliant installation.

Using pro-grade tools — digital manometer, leak detector, tubing cutter, and pipe wrenches — I mounted the tankless unit with vibration-resistant brackets, set the condensate drain, and installed a pressure relief valve. I insulated exposed lines to reduce heat loss and verified proper combustion air and exhaust routing.

I also reviewed best practices for maintenance: periodic descaling of the heat exchanger, cleaning inlet screens, and checking unions for tightness. Proper venting, gas pressure, and water filtration are the keys to longevity with any tankless water heater. Below are snapshots from the job with notes on steps and materials.

Mount & Prep

I located studs, set lag bolts, and leveled the backplate to secure the Gen 3 Tru Tankless. Planning intake/exhaust, hot/cold tie-ins, and the condensate drain ensures a vibration-free, code-compliant installation that protects soldered joints and compression fittings.

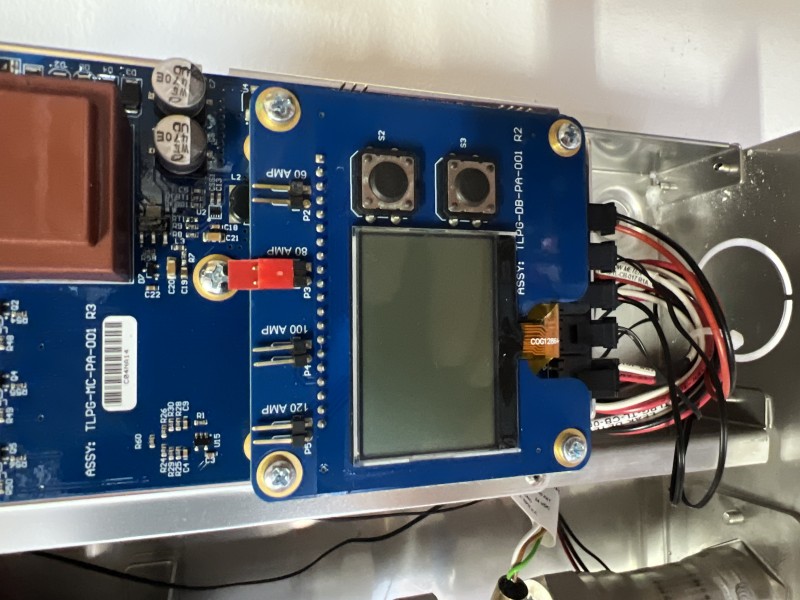

Diagnostics & Sizing

With a pressure gauge and digital manometer, I verified water pressure and gas supply for proper ignition and GPM. I inspected copper/PVC for corrosion, confirmed backflow prevention, and laid out clean tie-ins for the tankless conversion.

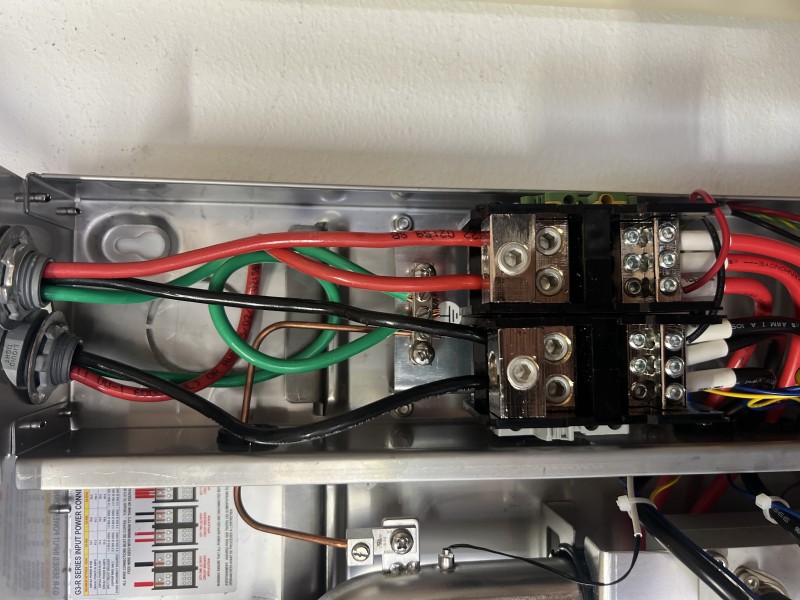

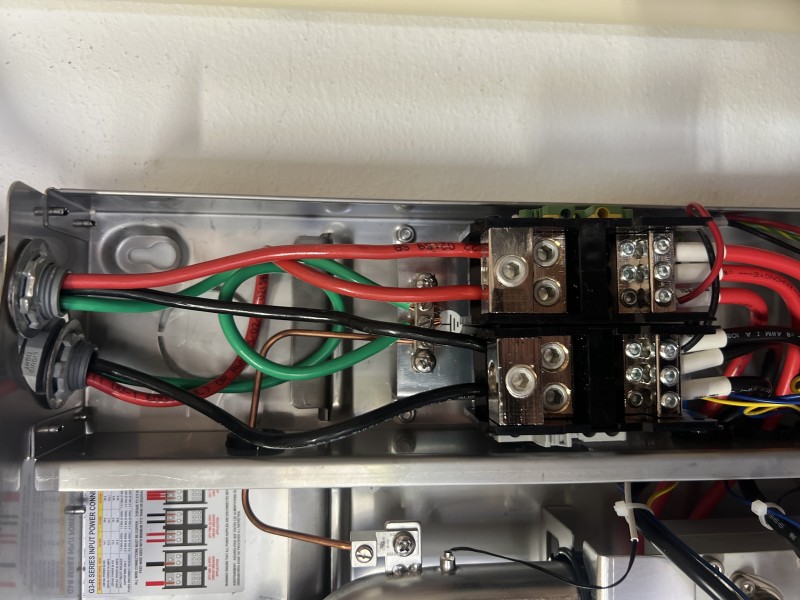

Water Connections

I set hot/cold supply lines with new copper elbows, used thread sealant on threaded fittings, and sweat joints with clean flux. After a pressure test, I insulated exposed piping to reduce heat loss and maximize tankless efficiency.

Gas Line & Safety

I installed a gas flex line, torqued unions, and performed a soap test followed by a digital leak detector sweep. Correct gas pressure and sealed fittings are vital for safe combustion and stable outlet temperature.

Venting & Condensate

I routed exhaust per manufacturer specs, verified intake clearances, and set the condensate drain with proper slope. Good venting protects the heat exchanger and keeps efficiency high in coastal Florida conditions.

Startup & Commissioning

After purging air and re-pressurizing lines, I powered up the unit and used diagnostics to verify ignition, outlet temperature, and GPM. Final checks included PRV function, backflow protection, and filter screens for quiet, dependable hot water on demand.