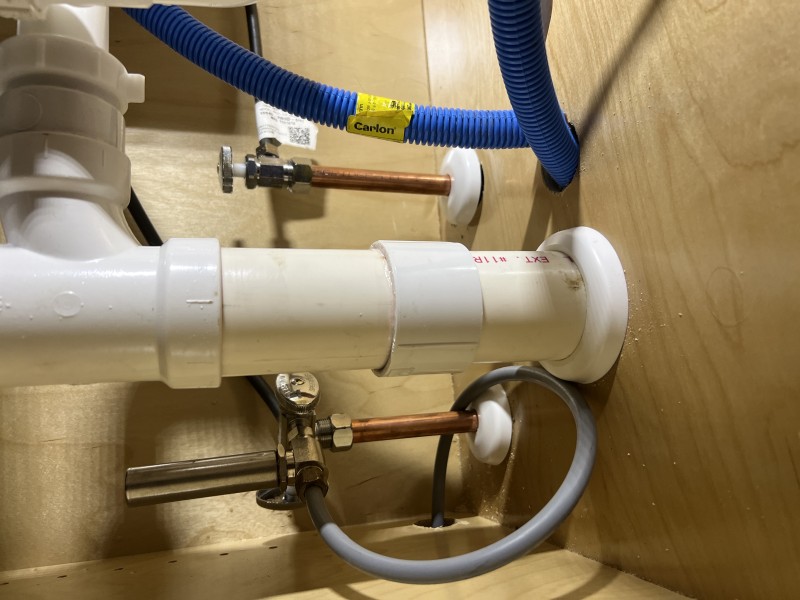

For this recently completed kitchen project, our licensed plumbers capped existing water lines, verified shutoffs, and then reinstalled the sink, faucet, dishwasher connection, and a new garbage disposal. We followed best practices for leak prevention, sanitary drainage, and clean under-sink organization using chrome angle stops, dual stops, escutcheons, a tubular P-trap, and an end outlet waste kit.

We pressure-tested supply lines, confirmed proper pitch on the waste arm, and used a Studor vent to maintain trap seal and airflow where venting constraints existed. Materials included copper/PEX adapters, PTFE thread seal tape, PVC primer and cement, a 2″ × 1½″ sanitary tee, flanged tailpiece, and new mounting hardware. Tools on site: adjustable and basin wrenches, pipe cutter, level, torque driver, and leak detection dye.

Our approach prioritizes code-compliant installation, neat routing, and future serviceability. We label shutoffs, align slip-joint fittings for easy maintenance, and confirm dishwasher air gap or high-loop routing as required. Final checks include disposal wiring verification, GFCI status confirmation, and a full fill-and-drain test to validate performance under real use.

If you’re planning a kitchen update in Lakeland, FL, our team delivers reliable fixture installation, garbage disposal replacement, dishwasher hookup, and line capping with top-tier craftsmanship and attention to detail.