Outdoor Hose Bib Repair in Brandon, FL — August 2025

We responded to a service call in Brandon, Florida for an exterior hose bib (outdoor spigot) that was running continuously. Continuous flow from a “relaxed” or partially open handle wastes water, stresses the valve seat, and can create erosion around landscaping and the foundation. Our goal was to diagnose the source of the flow and restore a proper shutoff using best‑practice plumbing repair techniques.

After isolating the line, we disassembled the spigot using an adjustable wrench and slip‑joint pliers to inspect the valve stem, packing nut, stem washer, and vacuum breaker/anti‑siphon assembly. UV exposure and corrosion can flatten a washer and score a valve seat over time, leading to drips or a steady stream. We replaced the worn components, refreshed the packing, and lubricated threads with plumber’s grease for smooth operation.

Before reassembly, we checked backflow protection to ensure safe potable water. We re‑seated the stem, verified the handle travel, and performed a cold‑pressure test with a gauge to confirm a tight seal at the valve seat. Proper shutoff protects against hidden leaks, inflated utility bills, and moisture issues that invite pests or mildew.

To keep outdoor fixtures reliable, we recommend seasonal checks, turning the handle fully clockwise after use, and inspecting the anti‑siphon device. Quality parts—like a neoprene washer and fresh packing—paired with careful diagnostics help extend the life of an exterior spigot and prevent future callbacks.

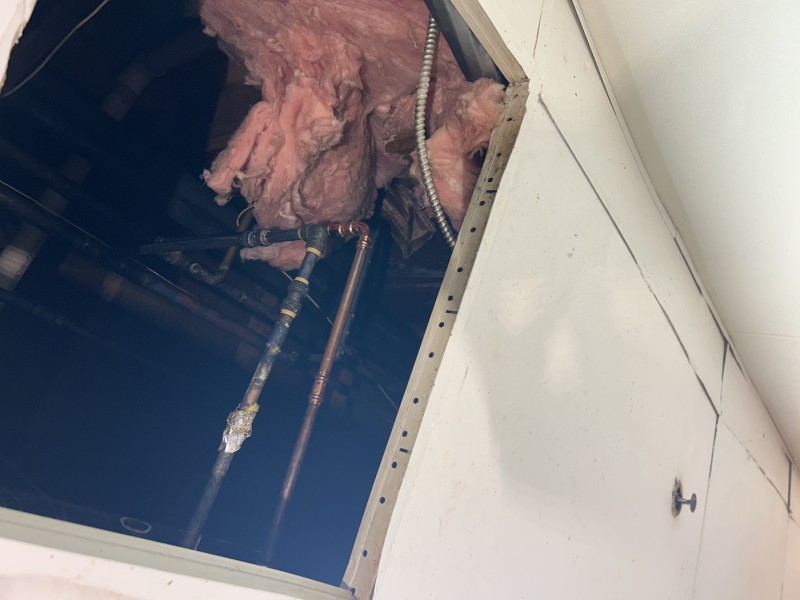

Initial Inspection — Continuous Flow

On arrival, we confirmed a steady stream from the hose bib, indicating a compromised valve seat or a handle left in a relaxed position. We isolated the line and checked for corrosion at the packing nut and stem threads to plan the spigot repair.

Disassembly with Hand Tools

Using an adjustable wrench and slip‑joint pliers, we removed the handle and loosened the packing nut to extract the valve stem. Careful disassembly prevents thread damage and sets up a clean rebuild with new packing and lubrication.

Washer & Seat Diagnosis

We found a hardened, flattened washer that could not seal against the valve seat. Replacing it with a durable neoprene washer and cleaning the seat surface restores full shutoff and eliminates wasteful dripping or continuous flow.

Backflow Protection Check

We inspected the vacuum breaker/anti‑siphon to verify proper backflow prevention. Ensuring this device functions correctly protects the potable water supply during hose use, irrigation, or pressure fluctuations.

Reassembly & Pressure Test

After refreshing the stem packing, applying plumber’s grease, and re‑seating the stem, we restored water and performed a pressure test. The spigot now shuts off cleanly with a reliable, leak‑free seal.

rotate-90 to rotate-270 or rotate-180. URLs remain untouched.