Pressure Relief Valve Replacement — Leesburg, FL (August 2025)

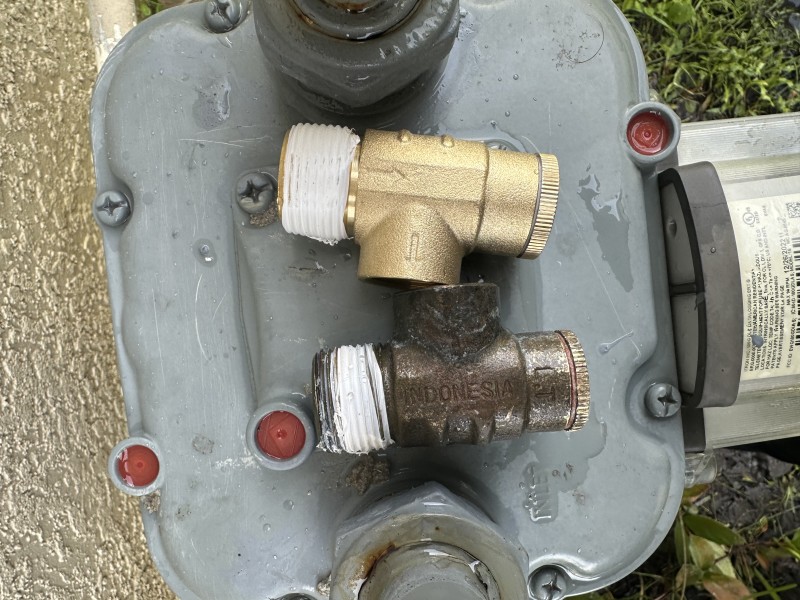

An active exterior leak developed near the main water line. On arrival, I confirmed the source as a failing pressure relief valve (PRV) and began a safe shutdown to protect the plumbing system.

I isolated the main, relieved pressure, and performed leak detection and water pressure testing to verify conditions. Central Florida’s hard water can accelerate corrosion, so I inspected threads and piping for scale, cleaned the joint, and prepared the connection for a code-compliant install.

After removing the failed component, I installed a new brass pressure relief valve with proper PTFE tape and thread sealant, ensuring a watertight fit without over-torquing. I then repressurized the system carefully and rechecked for any seepage.

Final checks confirmed stable static pressure and a dry connection. The home’s service line is now protected from over-pressurization and future leaks with a clean, professional repair.

Diagnosis & Leak Source

I traced the active leak to the PRV connection just downstream of the shut-off. Using a flashlight and mirror, I verified moisture at the threads and confirmed the pressure relief valve had failed, likely due to mineral buildup and age. Initial pressure gauge readings helped rule out other causes before proceeding.

Safe Shutdown & Removal

I shut off the main and relieved pressure at a low point to work safely. With pipe wrenches and channel-lock pliers, I backed out the corroded valve, protecting the service piping. I cleaned the seat with emery cloth and a wire brush to remove scale so the replacement would seal perfectly.

Code-Compliant Installation

I installed a new brass PRV, applying PTFE tape and pipe joint compound to achieve a reliable, watertight seal. Careful alignment and torque prevent cross-threading and future leaks. I verified clear discharge path and orientation consistent with plumbing best practices.

Pressure Test & Final Inspection

After slowly restoring service, I performed a static pressure test and visual leak check. The joint stayed dry under operating pressure, confirming a solid repair. I reviewed maintenance tips for thermal expansion and periodic pressure checks to keep the system protected in Leesburg, FL.