Commercial Urinal Valve Replacement in Brandon, FL

In July 2025, our plumbing crew completed a scheduled service call to replace two faulty Sloan urinal flush valves in a commercial restroom. Our work focused on enhancing water efficiency and resolving inconsistent flushing caused by worn-out diaphragm kits and outdated valve mechanisms.

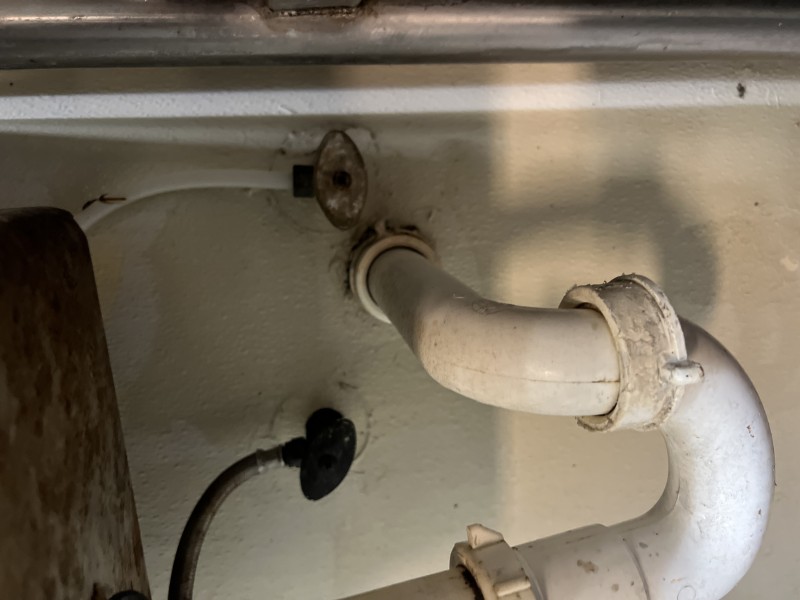

This photo shows one of the old Sloan urinal flush valves before we removed it. Signs of mineral buildup and slow flush response were clear indicators it needed replacement.

Here we carefully remove the flushometer body using a strap wrench to prevent pipe damage. Proper technique avoids leaks and ensures clean threads for the new valve install.

We prepped the water line and flushed the supply pipe to remove sediment before installing the new valve. This ensures full water flow and prevents internal damage to the Sloan diaphragm assembly.

Post-installation, we tested each Sloan flush valve for water pressure, timing, and smooth operation. Adjustments are key to achieving both performance and water savings.

A clean final install with chrome-plated hardware and no visible leaks. This Sloan Royal flushometer is ready for high-traffic use in a commercial setting.

Our toolbox includes adjustable pipe wrenches, channel locks, Teflon tape, and OEM Sloan parts. Each job gets done with precision and the right gear.

Cleanup is just as important as installation. We left the restroom spotless and the valves running like new—professional plumbing from start to finish.

This mounted flush valve is seated firmly with no play in the riser or tailpiece, ensuring long-term stability and efficient urinal function.

We handled both valves simultaneously, matching trim height and setting both to identical pressure to ensure uniform operation across urinals.

Every job ends with a walkthrough. We demonstrate flush operation to the client and confirm satisfaction before wrapping up our tools.